| |

Specialists in RTM and LRTM closed moulding. Suppliers of Injection Machinery,

Tooling, Training, Ancillaries and Turnkey solutions to the composites industry |

|

| |

RTM/Light RTM Injection Machinery RTM/Light RTM Injection Machinery

Megaject injection machinery - a range of pneumatically

powered injection machines with a variety of features ranging

from high to low output and the capability of injecting a wide

range of resin systems including filled or unfilled

polyester/vinylester, epoxy and phenolic.

Hypaject injection machinery range - Pre-mixed resin and

catalyst are drawn into the machine under vacuum, degassed

and then dispensed into the mould cavity. Suitable for small

batch production, R&D and aerospace moudling applications. | |

| |

>>Click on Picture to View Full size |

|

| |

RTM/Light

RTM Injection Machinery RTM/Light

RTM Injection Machinery

Resin Transfer Moulding (RTM)

is a low pressure moulding process where a mixed resin and catalyst

are injected into a closed mould containing a fibre pack or preform.

When the resin has cured the mould can be opened and the finished

component removed.

The process is suitable for simple GRP mouldings through to complex

structural components for the automotive and aerospace industries.

A wide range of resin systems can be used including polyester, vinylester,

epoxy, phenolic and methyl methacylates

etc, combined with pigments and fillers including aluminium trihydrates

and calcium carbonates if required.

The fibre pack can be either, glass, carbon, arimid, or a combination

of these. There are a large variety of weights and styles commonly

available.

|

|

|

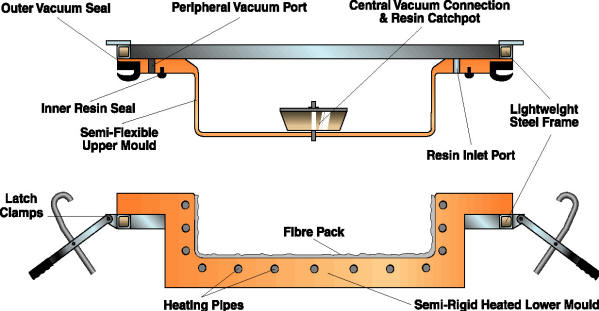

LRTM (Light Resin Transfer Moulding) |

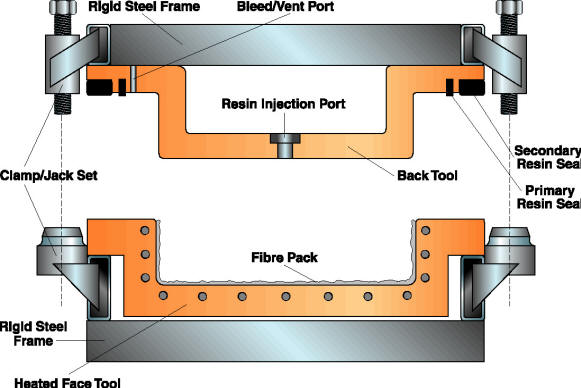

RTM (Resin Transfer Mould) |

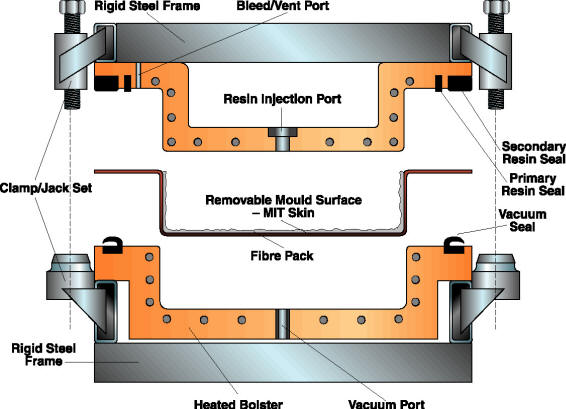

MIT (Multi Insert Tooling) |

RTM/LRTM Training

RTM/LRTM Training

The Light RTM process has become significantly

more popular within our industry as a complimentary process to RTM.

This hands-on course will focus on the precision and accuracy needed

to produce a Light RTM mould from preparation of the master pattern,

through to the commissioning of the mould.

The presentation will be of our latest Light RTM technology during

the

theoretical sessions, and hands-on tool-making techniques and

demonstration mould injections in our workshop.

|

|

| |

Download

files

|

Magaject RTM-Pro

Incorporated programmable logic controls in fully automatyic

production system |

|

Magaject MkV Polyeter Autohead

Designed for injection Polyester, Vinylester and Mathaacrylate

resin system and catalyst at controlled pressures, this machine

mixes on demand at injestion head |

|

Magaject SSB Patriot

Designed for injection Polyester, Vinylester and Methaceylate

resin and catalyst at controled pressure, with autohand mixes

on demand at injection head with catalyst |

|

Turbo Autosprue automatic injection valve

The Turbo Auto sprue is valve locks into the production mould

cavity and is controlled by the injection machine. |

|

Vacuuminder

The vacuuminder unit has developed specifically for use wuth

composites Light RTM moulding techniques also described as

'VERT' or 'VM'. |

|

PV Senser System

The PVSenser system has been specialcally designed to measure

precise pressures in mould. |

|

Vacuum Station

Vacuum station has been designed for high vacuum security

and optimized energy saving. Based upon two individual vacuum

pumps, for high vacuum and the other for medium vacuum use

the unit brings unparalleled features for the infusion and

Light RTM moulding industry. |

|

Siloject 121

The Siloject 121 has been specialcally designed to mix and

dispense the Momentivr Silopren RTV 2025 VBS material. |

|

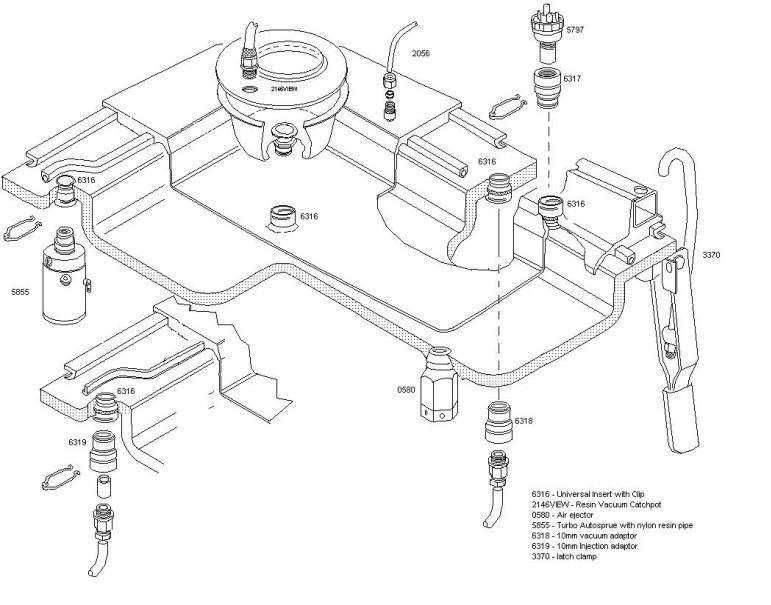

Light RTM Accessories

Silicone and neoplrene seals ensure that a 'close mould'

does as its name implied and keep the resin within the mould

|

|

Calibration Materials

These can be supplies either as wax sheet or cork sheet in

thickness. These materials are used when building the mould

to accurately determine the product thickness.

|

|

|

| |

Light

RTM Accessories

File Name |

File type

|

Download |

RTM today -Factoring Accuracy into

Polyester Moulding (598 Kb) |

PDF |

|

RTM today -European Centre for Brunswick

RIMFIRETM Preform Technology (548 Kb) |

PDF |

|

| RTM today -Desingner chairs choose RTM for quality finnish (530 Kb) |

PDF |

|

RTM today -Jeanneau’s closed mould production puts wind

in their sails (530 Kb) |

PDF |

|

| Driving productivity and business expansion

through Light RTM (74 Kb) |

PDF |

|

|

|

Neotech

Composite Co.,Ltd.

139 Soi Phrayasuren 30, Phrayasuren Rd., Bangchan Klongsamwa Bangkok 10510 Thailand

Tel : (662) 5174955-6 Fax : (662) 5174957 Mobile 086 3746588, 086 3152433, 086 3052248, 086 3108566

Download company catalog : Products list  , Ligth RTM , Ligth RTM  Honeycomb Honeycomb  , Tooling resin , Tooling resin

We are importer all materials for fiber glass industrial such as resin, gel coat, fiber glass, carbon fiber, aramid fiber, honeycomb, coremat, PVC foam, Balsa wood, tooling resin, tooling gelcoat, spray gel coat machine, vacuum materials.

We have retails and whole sells of our products all in Thailand country. |