|

Neotech

Composite Co.,Ltd.

139 Soi Phrayasuren 30, Phrayasuren Rd., Bangchan Klongsamwa Bangkok 10510 Thailand

Tel : (662) 5174955-6 Fax : (662) 5174957 Mobile 086 3746588, 086 3152433, 086 3052248, 086 3108566

Download company catalog : Products list  , Ligth RTM , Ligth RTM  Honeycomb Honeycomb  , Tooling resin , Tooling resin

We are importer all materials for fiber glass industrial such as resin, gel coat, fiber glass, carbon fiber, aramid fiber, honeycomb, coremat, PVC foam, Balsa wood, tooling resin, tooling gelcoat, spray gel coat machine, vacuum materials.

We have retails and whole sells of our products all in Thailand country.

Lantor

NL Lantor

NL

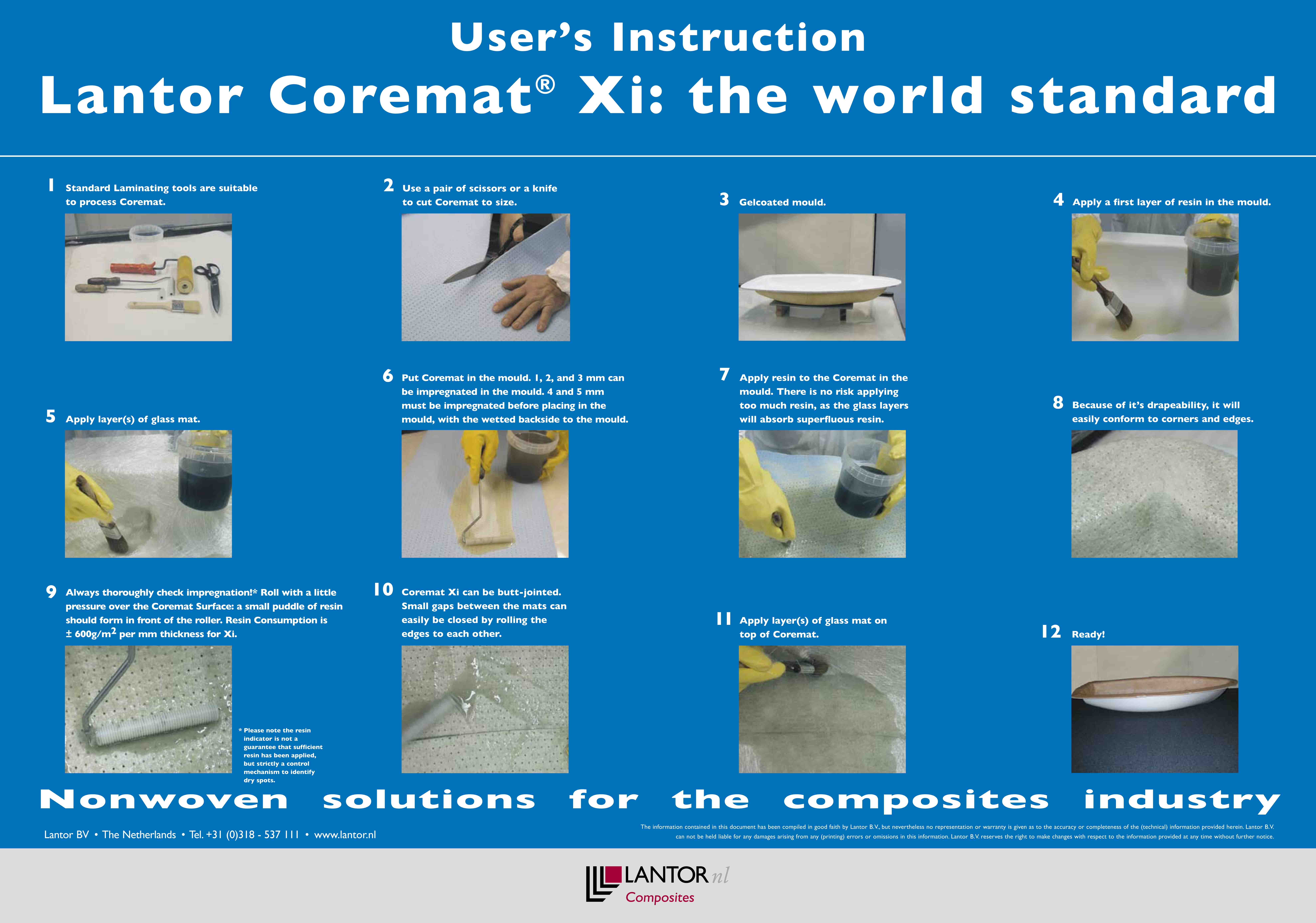

Lantor Coremat®

The nonwoven core and liner for hand lay-up and spray-up processes |

|

Coremat is a polyester nonwoven that contains

microspheres and is used as at thin core (bulker mat) or

print blocker (liner) in fibre reinforced laminated, manufactured

in Hand Lay-Up or Spray-Up processes. Coremat should always

be fully impregnated with resin.The microspheares in Coremat

prevent excessive resin up-take. The most important resons

to use Coremat are:

- Weight saving

- Resin and glass saving

- Increase stiffness

- Fast thickness build-up

- Excellent surfase finish

|

| |

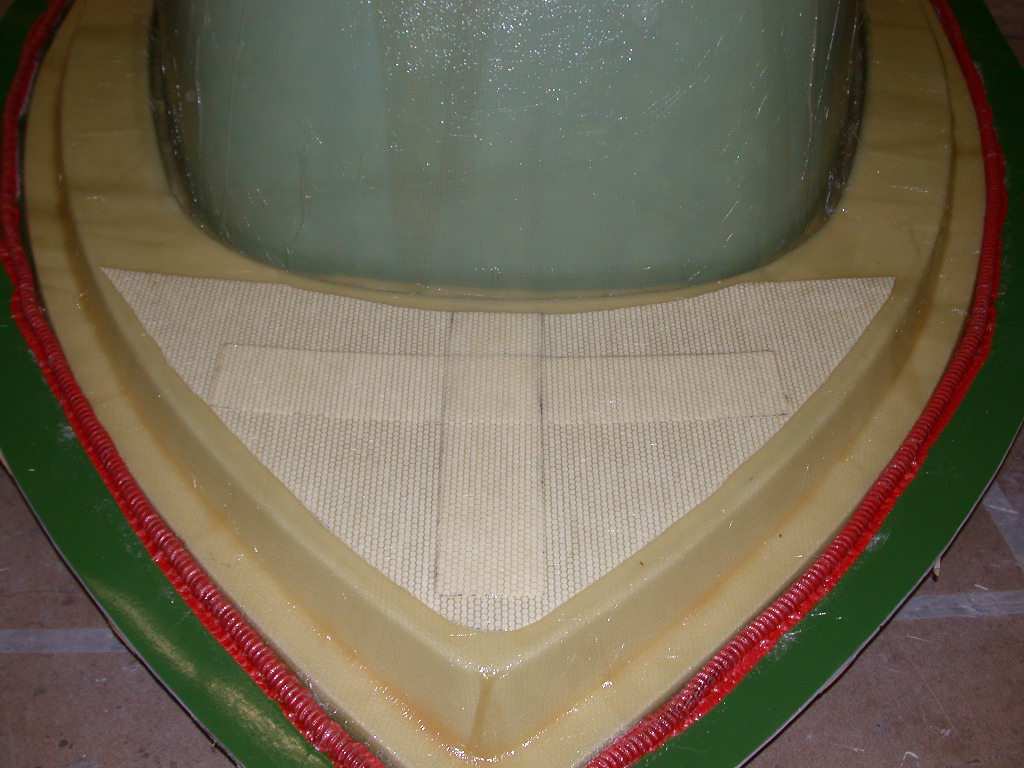

Coremat Xi |

ccc |

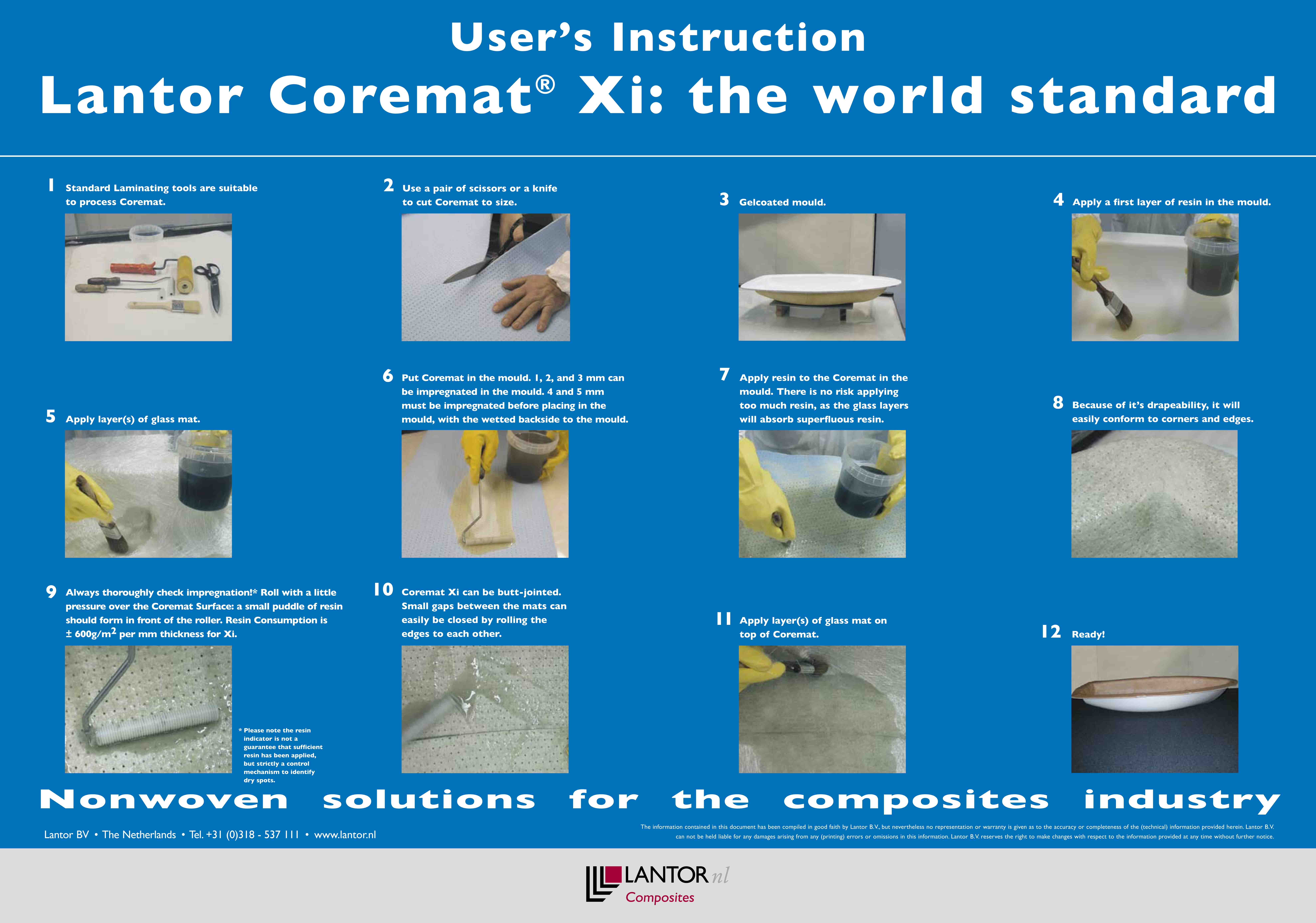

Coremat Xi is the world standard for bulk mats. The Coremat

resin consumption is about 600 grams per mm thickness. It

contains a resin indicator which changes colour to show

that resin has been applied to the Coremat.

Coremat Xi is very soft and pliable when it is wet and

therefore very suitable for complex shapes.

Key properties Xi:

Resin indicator

Excellent impregnation

High drapeability in resin

|

| |

|

|

|

| |

|

|

|

| |

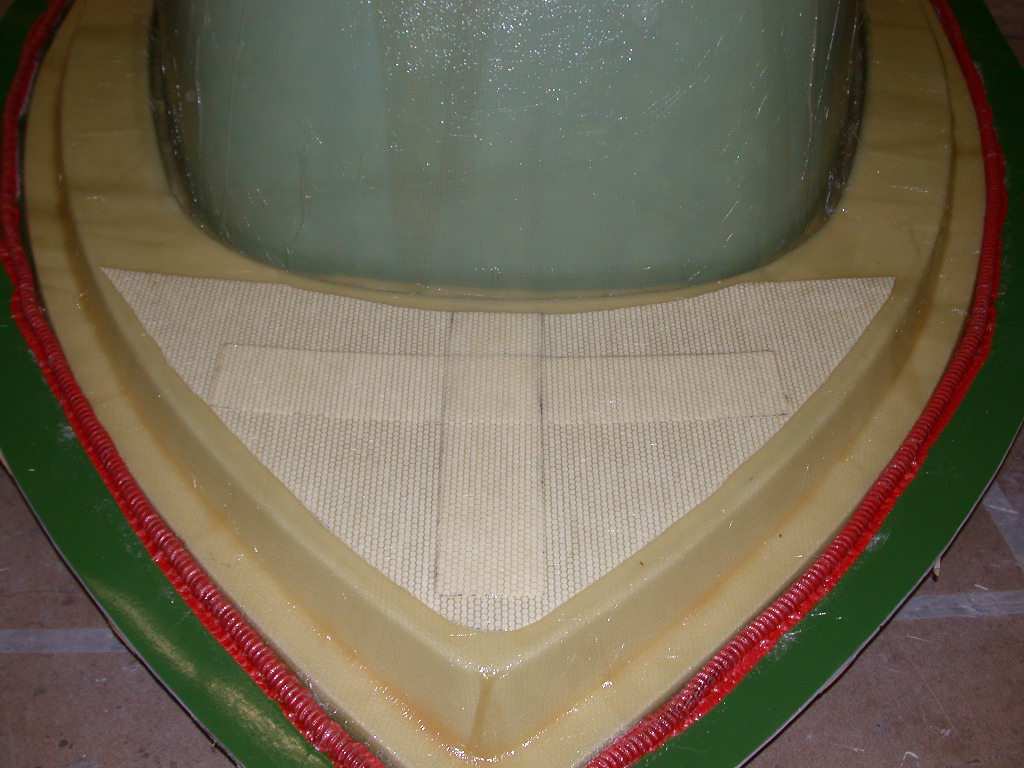

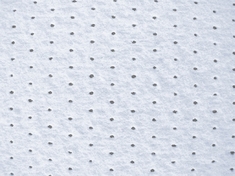

Coremat

XM Coremat

XM |

|

Coremat XM has a low resin take up: 500 gram of reain

per mm thicknerss. It is therefore suitable for weight critical

application . The hexagonal cell pattern resuls in a very

consistent thickness in the product. Coremat XM has very

good wet tensile strength properties; it is therefor often

used in application where mats are pre-wetted outside the

mould. Generally customers choose XM, because of its smoothness.

ease of working, and resin savings. Key properties XM:

- Honeycomb structure for

- excellent drapeability

- Extre resin saving

- High wet strength

|

| |

|

|

spec

coremat XM  |

| |

|

|

|

| |

|

|

Use Coremat XM 10 replace plywood of regid

materials like foam or plastic cores. Coremat has good secrew

retention and does not have rot issues, unlike wood. |

| |

Coremat

XM10 |

|

|

Lantor

Soric® Flexible Core

Core material

and infusion medium in one

Soric is a polyester nonwoven material with a compression

resistant hexagonal (XF, SF, LRC) or random dot-printed

(TF) cell structure. These pressure-resistant cells, which

are separated by channels, contain synthetic micro-spheres.

The cells do not absorb resin and therefore limit the total

resin up-take. Since these cells are pressure resistant,

they create thickness in the laminate even when pressure

is applied by vacuum bag. The channels facilitate resin

flow and form a pattern of cured resin with good mechanical

properties and excellent bonding to the outer skins.

Because of these unique properties and characteristics,

Soric can be used as:

- Thin core (bulker), adding

stiffness, while reducing weight

- Inter-laminar resin flow

medium, eliminating the need for other (disposable) flow

media

- Print blocker (liner),

that meets the most demanding cosmetic and finish requirements.

|

|

Soric

SF |

|

|

|

|

Soric SF is the general purpose grade, balancing

resin flow and surface quality. Soric SF is therefore especially

suitable for thinner laminates.

|

|

|

Soric

XF |

|

|

|

|

Soric XF maximises weight reduction in structural core

applications. Soric XF offers the fastest resin flow for

the lowest resin consumption, and is therefore ideal for

thicker laminates.

Soric TF

|

|

|

Soric

TF |

|

|

|

|

Soric TF is the ideal product for the most demanding

cosmetic and surface finish requirements. Soric TF can be

used as a core, but is most often used as a print blocker

in infused laminates.

|

|

|

Soric

LRC |

|

|

|

|

Soric LRC is the latest grade in the Soric product line.

Soric LRC has a resin uptake of about 350 g/m2/mm.

Soric LRC is now commercially available in thicknesses of

1.5 mm, 2 mm and 3 mm.

You will find our new products Lancore and FR-Soric under

Products & Processes.

|

|

|

Download

Brochue All Products Range Lantor Composites "Coremat-Soric-Finishmat"

Download

Application Manual of Lantor Products

Download

Technical Properties of Soric

Download

Coremat Heat Resistance

Download

Thermal Insulation of Coremat

Download

Screw Holding Capacity of Coremat

Download

Certificate ABS (Coremat Xi)

Download

Certificate Lloyds (Xi)

Download

Certificate Lloyds (XM)

Download

MSDS of Coremat Xi

Download

MSDS of Coremat XM

Technical

data |

|

Coremat

Xi |

Coremat

XM |

Soric

SF

|

Soric

XF

|

Soric

TF

|

| |

|

Xi 1 |

Xi2 |

Xi3 |

Xi4 |

Xi5 |

XM2 |

XM3 |

XM4 |

XM10 |

SF2 |

SF3 |

XF2 |

XF3 |

XF4 |

XF5 |

XF6 |

TF1.5 |

TF2 |

TF3 |

| Thickness |

mm |

1.4 |

2 |

3 |

4 |

5 |

2 |

3 |

4 |

10 |

2 |

3 |

2 |

3 |

4 |

5 |

6 |

1.5 |

2 |

3 |

| Roll length |

m |

130 |

80 |

50 |

40 |

30 |

80 |

50 |

40 |

15 |

80 |

50 |

80 |

50 |

40 |

30 |

25 |

100 |

80 |

50 |

| Roll width |

m |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1 |

1.27 |

1.27 |

1.27 |

1.27 |

1.27 |

1.27 |

1.27 |

1.27 |

1.27 |

1.27 |

| Resin uptake |

kg/m2 |

0.8 |

1.2 |

1.8 |

2.4 |

3.0 |

1 |

1.5 |

2 |

6.5 |

1.0 |

1.3 |

1.0 |

1.4 |

1.9 |

2.4 |

2.8 |

0.8 |

1.0 |

1.4 |

| Dry weight |

g/m2 |

35 |

62 |

88 |

114 |

125 |

96 |

128 |

163 |

335 |

130 |

170 |

130 |

190 |

260 |

320 |

375 |

90 |

115 |

170 |

| Density impregnated |

kg/m3 |

630 |

630 |

630 |

630 |

630 |

540 |

540 |

540 |

680 |

700 |

600 |

600 |

600 |

600 |

600 |

600 |

700 |

700 |

700 |

| Typical machanical

propertied of Lantor Coremat and Soric impregnated with unsaturated

polyester resin |

| Machanical

properties |

|

Xi |

XM |

SF |

XF |

TF |

Test

method |

| Flexural

strength |

MPa |

11 |

8.5 |

16 |

8 |

19 |

ASTM D790 |

| Flexural

modulus |

MPa |

1100 |

1250 |

1000 |

800 |

1500 |

ASTM D790 |

| Tensile

strength acroos layers |

MPa |

4 |

4 |

6 |

4 |

7 |

ASTM C297 |

| Compression

strength (10%strain) |

MPa |

10 |

10 |

4 |

8 |

4 |

ISO 844 |

| Shear

strength |

MPa |

5 |

3 |

6 |

3.5 |

7 |

ASTM C273-61 |

| Shear

modulus |

MPa |

35 |

25 |

40 |

35 |

34 |

ASTM C273-61 |

Lantor Composites in

the marine market

Naval

Lantor core materials can be applied to all composite parts,

including Cruise/ferry ships

- interior panelling, floor, ceiling, seating, doors, decks,

hulls, hatch covers, steering consoles, shower cabinets

and chairs.

Lantor Coremat® is used as a core material in decks

and hulls or as a print barrier in hull sides.

Lantor Soric® is used in closed mould processes as a

flexible core, interlaminar infusion medium and print barrier.

|

|

| |

Typical key benefits from using Coremat or Soric:

- Saves labor

- Saves weight

- Excellent print blocker

- Saves resin and glass

- Soric as an interlaminar infusion medium Lantor Finishmat®

D7760 is used in closed mould processes to prevent print

through effect and provide the laminate with a class-A finish.

For additional information on print through blocking and

osmosis prevention with Lantor Soric TF and Lantor Finishmat

D7760

|

|

|

Case studies in marine

applications

|

....... |

Lantor Soric sailingboat

Charger Composites is the manufacturer of the Bjorndahl 2.4

mR sailing boat. It is

located in central Finland on the Gulf of Botnia, the boat

building Mecca of Europe.

The philosophy of the company is to build great boats that

will last a lifetime!

Download

full details  |

|

|

Lantor Soric in motor boat

deck

Conyplex in Medemblik is a very innovative company, and were

the first boat builder

in The Netherlands to use the vacuum infusion process. The

boat shown was

produced by Conyplex for Van Wijk in Woubrugge.

Download

full details  |

|

|

Lantor Soric in marine boom

Novis Marine, manufacturers of the C&C and Tartan line

of performance and cruising sailboats in Fairport Harbor,

Ohio, has successfully achieved the goal of an integrated

mainsail storage system. It is achieved by engineering

on stiffness with high end materials like Carbon fibre weavings

in combination with epoxy resin and Soric XF

core/infusion medium.

Download

full details

|

| |

|

|

| |

|

|

Transportation

Soric® Flexible Core is a core material (bulker), infusion

medium and print blocker (liner) and is suitable for VI, RTM light,

RTM Heavy and Pultrusion.

Unique to Soric® Flexible Core is the combination of the following

qualities:

- Drapeability

- Weight saving properties

- Thin

- Flow medium

- design freedom

- light construction

- light construction

- processing support

All aspects of importance in composite applications of approximately

3 - 6 mm occur in the transportation market and its segments,

namely:

Automotive

cars, sport cars, niche cars

- panelling, spoilers

Transport

Truck, commercial vehicles, bus, RV

- panelling, spoilers, skirts, floor, doors

Mass Transit

Trains, trams, light rail

- panelling, seating, ceiling, floor, door

Specialty

Agricultural, sport & leisure, industrial

- hoods, roofs, bonnets

Case Study in Transportation

|

...... |

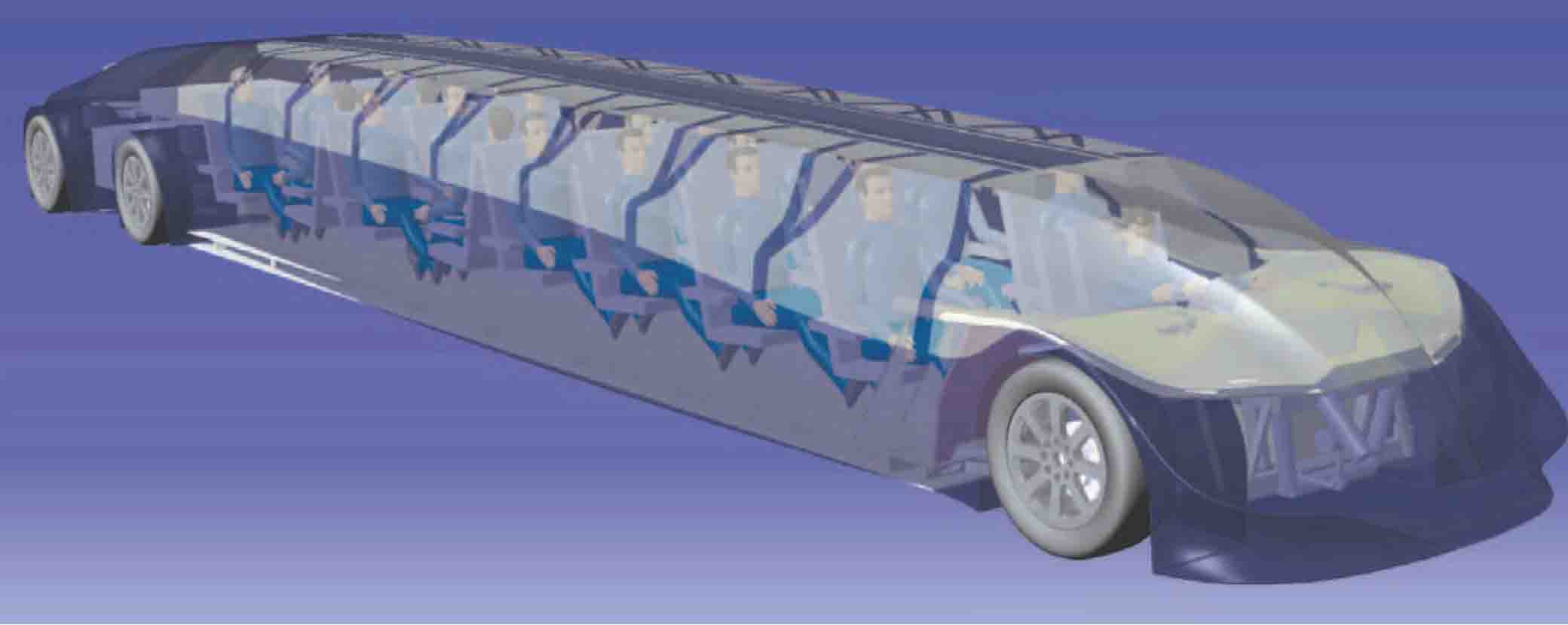

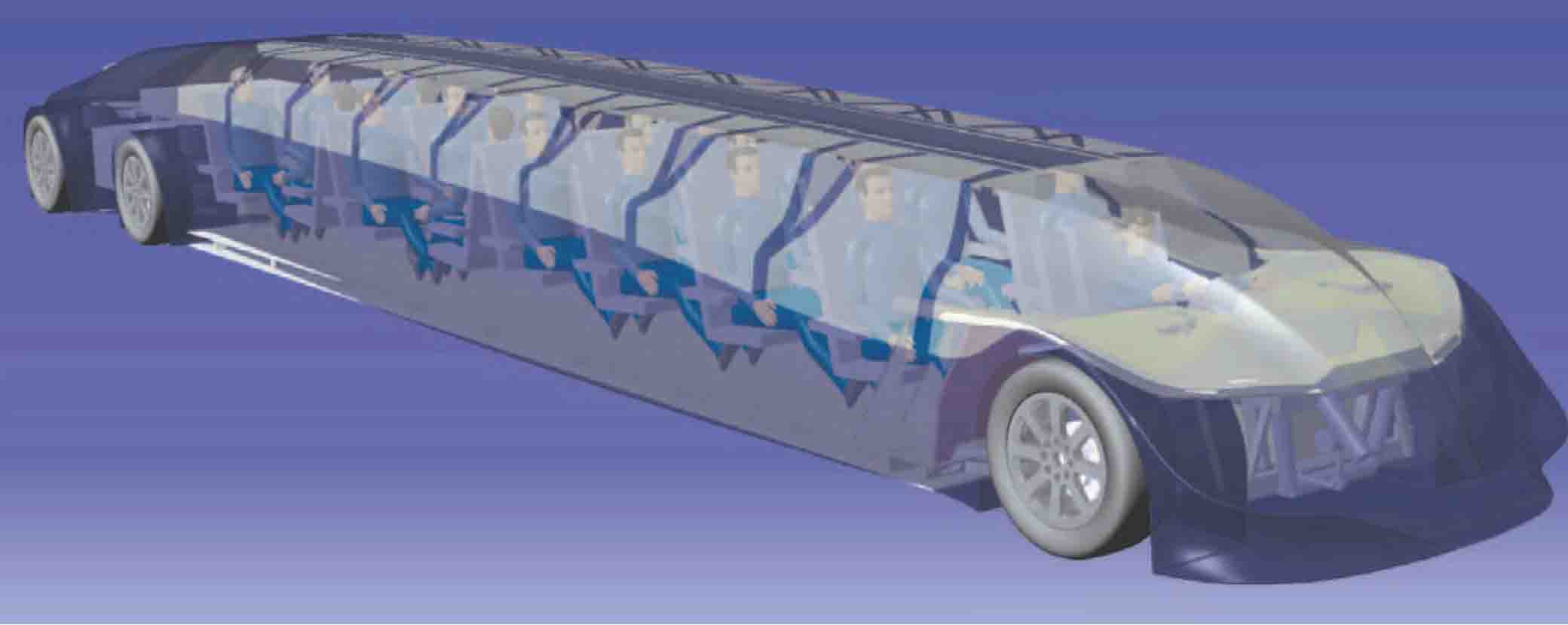

Lantor Soric in Superbus

project

Lantor Soric will be used as core material in the dutch

Superbus project. Lantor Soric suits perfect in this light

weight full composite application.A new type of public transport

is being developed in the Netherlands by the

TU Delft which relies on lightweight composite construction

and will be

demonstrated at the Beijing Olympics in August 2008. In

the search for a non-polluting, fast, economic and appealing

new means of public transportation, a project has started

in the Netherlands for the realisation of an electric vehicle

called Superbus.

Download

full details  |

|

|

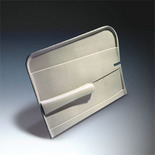

Lantor Coremat in bus parts

Fiberbus Brazil builds various bus parts, using spray-up,

hand lay up and RTM Light production processes. In their

open mould production they use Lantor Coremat to create

extra stiffness in i.e. stairs, bus front-covers or parts

where they need extra thickness for screwing in handle bars

and grips

Download

full details

|

|

|

Lantor Soric in trailer

floor

Soric was used in the floor of a luxury trailer. The trailer

is produced in South Africa for the Export market. Soricwas

taken into the development of the trailer floor, in this

way an optimal product could be designed.

Download

full details

|

|

|

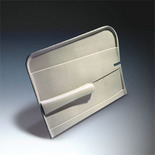

Lantor Soric in Mack truck

Marky Industries produces the bonnet of the Mack truck in

RTM Light.

Mack Trucks is one of the world's leading truck-manufacturing

companies and is currently a subsidiaryof AB Volvo, Volvo

Group

Mack Trucks is a top producer in the vocational, onroad-vehicle

market, Class 8 through Class 13. It is also the most popular

manufacturer of heavy-duty off-road trucks in America. Parts

for Mack’s righthand-drive vehicles are produced in

Brisbane, Queensland, Australia, for worldwide distribution Download

full details  |

| |

|

|

Aerospace

Business jets, freight, passenger planes

- interior panelling, focussed stiffening

|

Case

Study in Aerospace |

|

|

|

..... |

Lantor Coremat and Soric in

PAC – 750 XL aircraft

Fibre Glass International produces parts for the PAC 750 XL

aircraft (Pacific Aerospace Company) The design made its maiden

flight in 2001.The PAC 750 received full US FAA certification

in 2004. The type was targeted initially to the narrow market

of skydiving. In the parachuting role, the high-lift wings

and relatively high power to weight ratio enable the PAC 750

to take a load of parachutists to 12,000 feet (3,700 m) and

return to land within 15 minutes.Download

full details  |

|

|

Lantor Coremat

in UAV

The Aerostar Tactical Unmanned Air

Vehicle System (TUAV) provides reliable, high quality real

time intelligence gathering capability. The system was developed

by the Company’s leading engineers in cooperation

with the Israeli Intelligence Corps. The system has accumulated

thousands of operational hours, giving the system its maturity,

reliability and credibility. Among the system’s customers

are the IDF, U.S. Navy, Angola and other customers around

the globe.

The Aerostar has a wing span of 7.5 m and uses Coremat XM

to create the right stiffness needed for the wings, without

adding o lot of extra weight. The wings are made of a carbon-epoxy

system.Download

full details  |

| |

|

|

| |

|

|

|

Coremat

XM

Coremat

XM