Neotech

Composite Co.,Ltd.

139 Soi Phrayasuren 30, Phrayasuren Rd., Bangchan Klongsamwa Bangkok 10510 Thailand

Tel : (662) 5174955-6 Fax : (662) 5174957 Mobile 086 3746588, 086 3152433, 086 3052248, 086 3108566

Download company catalog : Products list  , Ligth RTM , Ligth RTM  Honeycomb Honeycomb  , Tooling resin , Tooling resin

We are importer all materials for fiber glass industrial such as resin, gel coat, fiber glass, carbon fiber, aramid fiber, honeycomb, coremat, PVC foam, Balsa wood, tooling resin, tooling gelcoat, spray gel coat machine, vacuum materials.

We have retails and whole sells of our products all in Thailand country.

The Concept

| |

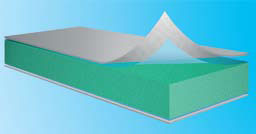

DIAB advanced core materials, when

used with high strength skins, provide the ideal combination

of strength, stiffness and toughness. DIAB structural cores

and composites sandwich solutions work by increasing the performance

of composite parts while optimizing weight.

In principle a sandwich consists of two skins or facings

with a core material in between. The skins take up normal

stresses and give the structure a hardwearing surface. The

core material absorbs the shear stresses generated by loads,

distributing them over a larger area.

Compared to single skin laminates, the sandwich concept

offers substantial improvements in both flexural rigidity

and flexural strength. By doubling the thickness of the

core, the improvements are even greater yet the weight increase

is negligible. |

|

|

|

| |

|

Key

Benifits |

|

|

High Strength to Weight Ratio

The higher strength-to-weight ratio of the sandwich concept

can be used in a variety of ways - higher speeds, longer

range, greater payload capacity or reduced power demand

– all of which give better operating economy. DIAB

sandwich composites also offer:

Good Dynamic Strength

DIAB core materials have good dynamic properties making

them ideal for applications where shock and impact loads

could be experienced.

Low Water Absorption

Divinycell and Klegecell core materials are both closed

cell materials and are therefore virtual impervious to the

ingress of moisture.

Excellent Insulation

The good insulation and acoustic properties of DIAB core

materials eliminate the need for additional insulation materials

that normally add extra weight to the structure. |

|

|

|

|

| |

Performance Advantaged |

|

|

| |

The DIAB sandwich concept is one of the best ways to reduce

weight whether it is used for structural members or interior

paneling. But this is just the first step in the weight saving

spiral. The DIAB sandwich concept also inherently increases

stiffness and provides excellent sound and thermal insulation

properties thus eliminating the need for subsidiary materials.

This further weight reduction results in even lower energy

consumption and consequently a much lower environmental impact.

This saving in weight can be used in a wide variety of

ways including:

• Higher speeds

• Longer range

• Better fuel economy

• Larger payloads

In addition DIAB sandwich composites require the minimum

of maintenance and repairs can often be carried out easily

without any loss of structural integrity. |

|

|

|

|

Production

Benifits |

|

|

Freedom of Design

The inherent nature of sandwich composites gives designers

and engineers tremendous freedom in terms of both form and

function. Compound curves can be readily incorporated. Also

as the outer skins can be orientated to align with the load

paths, structural integrity and performance can be maximized.

Production Flexibility

Components can be manufactured using low cost tooling. A

wide variety of manufacturing processes can be employed

including hand and spray laminating, vacuum consolidation,

press molding and resin infusion.

DIAB sandwich core materials are also compatible with all

commonly used composite materials including polyester, vinylester

and epoxy resin systems and glass, aramid and carbon fiber

reinforcements.

Less waste

DIAB core materials can be supplied in ready to use kits.

This reduces fabrication times, saves labor, improves quality

and virtually eliminates scrap. |

|

|

|

|

|

| For more than 30 years Divinycell H has been

the first choice of leading producers of sandwich composite

structures around the world. During this time the properties

of Divinycell H have been continuously enhanced and improved

so that it continues to be ideal for the vast majority of

sandwich composite applications.

Ideal for a Wide Range of Applications

Divinycell H has been widely used over many years in virtually

every application area where sandwich composites are employed.

These include the marine (leisure, military and commercial),

land transportation, wind energy, civil engineering/infrastructure

and general industrial markets.

Material & Process Compatibility

Divinycell H is compatible with virtually all commonly used

resin systems (polyester, vinyl ester and epoxy) including

those with high styrene contents. Its good temperature performance

with high residual strength and good dimensional stability,

makes Divinycell H ideal for hand laminating, vacuum bagging,

RTM (resin transfer molding) and other closed molding processes.

Mechanical Properties

In its application range Divinycell H has the highest strength

to density ratio. It exhibits at both ambient and elevated

temperatures impressive compressive strength and shear properties

(normally the most important for a sandwich core material).

In addition the ductile qualities of Divinycell H make

it ideal for applications subject to fatigue, slamming or

impact loads. Where a more brittle core material might well

shatter or delaminate as a result of an impact, the ductility

of Divinycell H allows it to absorb energy when deflected

without structural failure. Other key features of Divinycell

H include consistent high quality, excellent adhesion /

peel strength, excellent chemical resistance, low water

absorption and good thermal / acoustic insulation.

Full details of the core's properties are contained in

the comprehensive Divinycell H Technical Manual that can

be downloaded here.

Widest Range of Densities

Divinycell H is available in an ultra-wide density range

- 38 to 250 kg/cu.m. This enables designers to optimize

the structure by choosing the correct density for their

application.

Standard & Special Finishing

Divinycell H sandwich core can be supplied with probably

the widest range of finishes available in the industry.

The aim is to facilitate and speed core installation, enhance

component quality / performance and to meet specific process

requirements. These include grid-scored, double cut and

'infusion' grooved/perforated forms.

Ready-Made Kits

For those involved in series production, Divinycell H can

be supplied in ready-made construction kits where each piece

is pre-cut, shaped, as necessary, and numbered to fit exactly

into its designated place in the mold. This substantially

reduces build times, saves labor costs, improves quality

and cuts waste.

File

Name |

File

type |

Download |

|

|

| Divinycell H specification |

PDF |

|

|

|

|

|

|

|

|

|

Divinycell P is a recyclable, thermoplastic

sandwich core material that is typified by excellent FST (fire,smoke

& toxicity) properties, a wide processing envelope and

very good fatigue properties. It is available in densities

from 60 to 150 kg/cu.m. (3.8-9.4 lb/cu.ft.) and offers good

acoustic/thermal insulation

properties, low water absorption, good mechanical characteristics

and chemical resistance.

Ideal for a Wide Range of Applications

Although suitable for a wide range of uses, Divinycell P

is a cost effective solution for sandwich composite applications

in the public transportation, wind energy and industrial/construction

markets.

The energy efficiency of a Divinycell P sandwich makes

it ideal for transport applications such as interior panelling,

floors and exterior panels for trains, trams, buses and

coaches.

In the wind energy market the excellent properties and

good processing characteristics of Divinycell P has meant

that it can be used in both blades and nacelles.

For industrial/construction applications, sandwich composites

based on Divinycell P provide not only lightweight solutions

but also give designers and architects new creative freedom.

Typical applications include domes, architectural claddings,

industrial housings, portable buildings and heating and

ventilation insulation.

Mechanical Properties

In addition to its good compression and shear properties,

Divinycell P has low water absorption and excellent acoustic/thermal

insulation properties. It exhibits at both ambient and elevated

temperatures impressive compression strength and shear properties.

Material & Process Compatibility

P is compatible with most commonly used resin systems (polyester,

vinyl ester, epoxy and phenolics) including those with high

styrene contents. It can also be processed using hand laminating,

vacuum bagging and closed molding processes such as infusion

and RTM (resin transfer molding).

With its high residual strength and good dimensional stability

at elevated processing temperatures, Divinycell P can be

readily used with a wide variety of 'industrial' medium

temperature prepreg systems. Furthermore, it can be thermoformed

and used in pultrusion molding.

Details of the core's properties are contained in the Divinycell

P data sheet that can be downloaded here.

Standard & Special Finishing

Divinycell P sandwich core can be supplied with a wide range

of finishes to facilitate installation, enhance component

quality and to meet specific process requirements. These

include grid-scored, double cut and 'infusion' grooved/perforated

forms.

Ready-Made Kits

For those involved in series production, Divinycell P can

be supplied in ready-made construction kits where each piece

is pre-cut, shaped, as necessary, and numbered to fit exactly

into its designated place in the mold. This substantially

reduces build times, saves labor costs, improves quality

and virtually eliminates waste.

File Name |

File type |

Download |

| Divinycell P specification |

PDF |

|

| |

|

|

|

ProBalsa

- End Grain Balsa Core |

| |

Balsa is a naturally recurring Ecuadorian resource.

The balsa plant grows from a seedling to a mature tree in

4-6 years reaching heights of up to 28 meters (90 ft) before

coming to the end of its natural life. ProBalsa is high quality

coring material made from end-grain balsa wood. Its end-grain,

micro-honeycomb structure offers exceptional strength and

stiffness. ProBalsa core can be supplied in flat sheets, in

grid-scored form and as kits. To access the ProBalsa brochure

(292k Acrobat pdf file), please click on the title above.

For technical data, please click here (60k Acrobat pdf file).

PB Lightweight

A low density balsa core (90 kg/cu.m. average) for weight

critical applications.

PB Standard

With an average density of 155 kg/cu.m., ProBalsa standard

provides and excellent combination of high strength and

low weight.

PB Heavyweight

A high density, high strength version of ProBalsa Standard

(220 kg/cu.m. average density) for highly loaded applications.

PB Plus

A version of ProBalsa that is micro-sanded and coated to

reduce resin absorption during lamination.

File Name |

File type |

Download |

| ProBalsa End Grain specification |

PDF |

|

|

|

|

|

| |

|

|

| |

|

|

| |

Neotech

Composite Co.,Ltd.

139 Soi Phrayasuren 30, Phrayasuren Rd., Bangchan Klongsamwa Bangkok 10510 Thailand

Tel : (662) 5174955-6 Fax : (662) 5174957 Mobile 086 3746588, 086 3152433, 086 3052248, 086 3108566

Download company catalog : Products list  , Ligth RTM , Ligth RTM  Honeycomb Honeycomb  , Tooling resin , Tooling resin

We are importer all materials for fiber glass industrial such as resin, gel coat, fiber glass, carbon fiber, aramid fiber, honeycomb, coremat, PVC foam, Balsa wood, tooling resin, tooling gelcoat, spray gel coat machine, vacuum materials.

We have retails and whole sells of our products all in Thailand country. |