| |

| |

ROBINSON EXTERNAL MIX SPRAY UP SYSTEMS

Low Pollution

Lower airless pressure by Robinson is designed to give lower P.P.M. count for environmental protection.

Safety

Engineered for the safest possible operation.

Save on Materials

Controlled airless spray pattern enables accurate deposition of materials resulting in less over-spray and therefore cost savings.

No Flushing

External mix requires no solvent flush.

Catalyst System

Well proven, instantly responsive flow meter or catalyst slave pump system.

Service

Efficient design means low maintenance and long service life. Full service back-up facility to all areas.

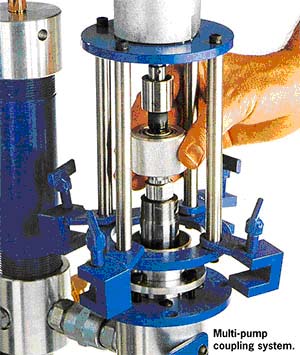

One-two-or as many pumps as you need.

This efficient multi pump unit enables resins and gelcoats to be pumped and sprayed without flushing of equipment. A quick release coupling system changes the motor from pump to pump resulting in change over time of one minute or less. It's compact and mobile.

Multi-pump system for chopper gun and gelcoat application. Multi-pump system for chopper gun and gelcoat application.

Specifications: |

System: |

Pneumatically operated requiring 18 C.F.M. |

Resin or Gelcoat System: |

Positive displacement double acting pumps. Ratios: L/P16:1 - H.P. .25:1 |

Catalyst System: |

Responsive flow meter or catalyst slave pump system. |

Glass Cutter: |

Pneumatic with speed and spray width controls. |

Unit Weight: |

48kg. Complete in packing box air shipping - 73kgs. |

Hose Length: |

Standard length - 9.metres |

|

|

| |

|

|

|

"Robo" Internal

Mix Chopper Gun

This unit sprays resin and gelcoat and chops gun rovings for

the commercial production of fibreglass articles.

The "Robo" Chopper Gun Gelcoater

has been developed in Australia over a 35 year period. Easy

to operate and simple to repair, this is Robinson's most popular

Chopper Gun, with thousands sold throughout the local region

and other parts of the world. With a thorough understanding

of what the operator wants, the HVLP (high volume low pressure)

concept has been well accepted.

The Robo Internal Mix Chopper Gun meets environmental pollution

standards. It can be used equally as well as a Gelcoater.Resin

Wet-out or Gelcoat spraying

The "Robo" Internal Mix is available without a chopper.

In this form it can be used as a resin wet-out gun or to apply

gelcoat.

Multiple Pumps with "Quick Colour Change"

The "Robo" Internal Mix Chopper Gun can be optioned

with multiple pumps for quick change from one colour to another.

Using the same air motor with quick-change fittings and separate

material lines going to the gun, it takes less than a minute

to change from one colour the next. Lines don't need to be

flushed, resulting in material savings. |

|

Saturator Internal Mix Chopper

Gun

The Saturator Unit has been designed for long life low maintenance

operation. The unit features a catalyst slave pump coupled to

the material pump, which requires virtually no monitoring. The

materials are delivered through an internal mix nozzle at very

low pressure. The Saturator Unit will create no blow back from

the job no matter what material output levels the unit is operating

at.Unit Choice

The Saturator is offered in either resin wet out form or combined

with a glass roving cutter for the depositor unit.

Low Pollution

We believe that with the use of L.S. E Resins, a very low

PPM count of Styrene is achievable and will meet all Governmental

standards. Internal Mix Due to the internal mixing of the

catalyst and resin, 100% of the catalyst is mixed thoroughly

with the resin which means superior quality laminates and

no catalyst vapor in the air.

Performance

Outputs of 2Kg to 6Kg/min enables operators to achieve top

performance on any size article. This Unit can be supplied

in high output form to accept 2 or 3 strands of glass.

Savings of Material And Time

Because of the precise flat fan pattern, material losses are

reduced to almost zero. Transfer efficiency with the Saturator

is vastly improved over all competitors due to the very low

velocity of the materials. By spraying large droplets to the

job with no air blowing vapor from the resin the Saturator

will achieve very high transfer efficiency with very low emissions.

Operation Simplicity of design and slave pump catalyst system

enables ease of operation and low maintenance. There is no

need for highly skilled operators. New pump design gives low

and high output performance and quiet operation an acetone

flush system is incorporated for easy cleaning of the nozzle. |

|

Internal mix Chip Filled

Gelcoater

Robinson have added a new dimension to the finish of kitchens,

bathrooms and fibreglass pools with the introduction of the

Chip Filled Gelcoater.

A Robinson Chip Filled Gelcoater

can spray chips and flakes up to 3000 microns in diameter

in a concentration of up to 40% of gelcoat giving a unique

finish. This exciting coating method results in a very attracative

finish to rival any other coating available today and is designed

as a one coat or multiple coat application.Operation

The Robinson Chip Filled Gelcoater is a low pressure internal

mix spray unit using the simplicity of the non-mechanical

catalyst flowmeter or if you wish a positive displacement

catalyst slave pump option.

Unique Design

A unique straight through system design enables chip, flake

or ceramic filled materials to be sprayed with a a size never

before achieved.

Pump

The purpose designed pump is all hard chromed finish internally

and features mechanical, tool steel valving.

Internal Mix

Internal mixing of the gelcoat and catalyst ensures a thorough

mix and results in excellent curing and possible savings on

catalyst. Finish The soft effect of the low pressure spray

gives excellent deposition retention, low profile finish and

total lack of lineage marks from spraying. |

|

Electronic Variable Ratio

Pour/Spray Equipment

The Robinson Electronic Variable Ratio Epoxy Dispenser unit

is an electrically driven twin pump unit of variable ratio

and output. This unit has two electronic invertor controlled

pumps delivering epoxy in a continuous on demand flow or optional

shot sizing to a hand held gun or fixed station output with

static mixers.

Epoxy Feed:

The unit can have various sizes of containers, hoppers and

drums to feed epoxy of varying viscosities into the pumps.

Versatility:

Robinson's EVR Epoxy units can be used from small epoxy injections

for electronics up to high capacity, high viscosity epoxy

glues for crusher back plates in mining smelters. Optional

roller applicators can be fitted for applying epoxy to floors,

composites manufacture and all industrial applications |

|

RTM Lite Dispensing Unit

The Robinson Lite Dispensing Unit is a system designed for low

pressure injection moulding. Catalysed resin is injected under

very low pressureby a 4:1 ratio resin pump into the closed mould

containing a pre-cut fiberglass matrix.

By using very low pressure or vaccuum assistance injection into

the mould, air is displaced completely by the resin without

the risk of pushing the fibreglass aside.

The resin impregnated fibreglass cures producing an even resin/fibreglass

matrix of quality and strength.

Materials are accurately used in the closed mould process when

using Robinson's RTM Lite Dispensing Unit. Wastage due to mixing

by hand or by spraying is eliminated giving considerable saving.

The simplicity of the Robinson's RTM Lite Dispensing Units enable

high quality, match moulded articles every time. |

|

GRFC Cavitation Mixer

The Robinson Cavitation Mixer is used in the mixing of cement

for GRC (Glassfibre Reinforced Cement) or GRFC (Glass Reinforced

Fibre Cement) spray or other mixing operations that require

a shear mixing action.

Variable Speed

This unit is a variable speed shear mixer that is controlled

by an electronic invertor requiring a current of 240 volts

x 50 cycles or suited to the electrical current of the country

of operation.

Pneumatic Hoist

A pneumatic hoist lifts the motor/mixer up and down for drum

placement and removal.

Digital:

The electronic invertor has an easy to read digital read-out

for control of the speed of the mixer from initial mix to

high speed shear mixing. |

|

Glass Reinforced Fibre Cement

Spray Unit:

The Robinson GRC or GRFC spray unit is a pump and spray system

for Glass Reinforced Fibre Cement that will spray the cement

slurry and chopped glass fibre onto a mould.

Torque

A long wearing cavity displacement pump is directly driven

by an electric motor controlled by a Variable Frequency Drive.

This method enables a small motor through a gearbox to drive

the pump with vastly increased torque.

Clean Up

Clean up of the S/S hopper and pump is extremely easy and

efficient.

Maintenance

Almost no maintenance is required on the pumping system as

there are no wearing seals.

Chopper

A pneumatic driven glass chopper is attached to the gun and

chops and sprays through the centre of the gun.

Cement slurry

Cement slurry is pumped and sprayed through an annular around

the chopped glass fibre resulting in a wetted sprayed matrix.

Versatile

The unit can be mobile with a pantograph boom or fixed station

with boom. |

| |

|

|

File Name |

File type |

Download |

| External Airmix spray system catalog |

PDF |

|

| Robo Internal mix catalog |

PDF |

|

| Electronic Variable Ration |

PDF |

|

| Saturator Internal mix |

PDF |

|

| Airless Internal mix catalog |

PDF |

|

| Air driven fiberglass chopper |

PDF |

|

| Resin roller attachment |

PDF |

|

| Special dispensing equipment |

PDF |

|

| Light RTM dispensing unit machine |

PDF |

|

| GRFC Cavitation Mixer |

PDF |

|

| Glass Reinforced Fibre Cement Spray Unit GRC |

PDF |

|

Neotech

Composite Co.,Ltd.

139 Soi Phrayasuren 30, Phrayasuren Rd., Bangchan Klongsamwa Bangkok 10510 Thailand

Tel : (662) 5174955-6 Fax : (662) 5174957 Mobile 086 3746588, 086 3152433, 086 3052248, 086 3108566

Download company catalog : Products list  , Ligth RTM , Ligth RTM  Honeycomb Honeycomb  , Tooling resin , Tooling resin

We are importer all materials for fiber glass industrial such as resin, gel coat, fiber glass, carbon fiber, aramid fiber, honeycomb, coremat, PVC foam, Balsa wood, tooling resin, tooling gelcoat, spray gel coat machine, vacuum materials.

We have retails and whole sells of our products all in Thailand country |